INDUSTRIES

Beverages & Powder Drink Mixes Manufacturing Equipment

Frequent recipe changes can result in high manufacturing costs and excessive inventory if not carefully managed.

MATERIALS HANDLING SYSTEMS

Powder beverages processing and blending equipment

Our hygienically designed powder handling and mixing system is all you need for the efficient production of powder-based beverages and drinks. By decoupling the processing steps, we enable companies to achieve a flexible manufacturing system.

With a growing appeal for more varied beverage and drink flavours as well as dietary trends including lactose-free and veganism, beverage manufacturers are having to change how they produce their products - from the processes they use to the industrial powder handling and mixing equipment they choose.

Increasingly large recipe portfolios mean many changeovers which significantly impacts production time.

Powder mix segregation is a risk, particularly with 3 in 1 coffee mixes, due to the different particle characteristics.

Problems with dust create cross-contamination risks, putting both employees and customers at risk.

- Quickly responding to consumer demand

- Many recipe variations due to large product portfolios

- Strict allergen control and regulatory restrictions

- Traditional systems limit flexibility

- Powder mix segregation

- Powder containment and dust in the factory

Matcon's bulk material processing IBC solutions are designed to optimize your production line to ultimately make it more flexible. By employing parallel processing, each manufacturing process step can take place independently to allow manufacturers to produce more than one batch or different recipe batches at any given time.

The system remains closed at all times as all powders are contained within the IBC, eliminating any risk for cross-contamination and offering dust containment for a cleaner environment and operator safety. As ingredients are fully contained within the IBC tumble blender, cleaning between batches is reduced.

With a wide range of IBC sizes available, we can accomodate different batch sizes and support pilot scale testing with seamless scale up.

Our unique Cone Valve Technology located within each IBC protects your blended powders against segregation during the discharge process, maintaining their integrity and quality. It offers automatic and controlled powder discharge, overcoming the traditional powder handling issues of bridging, rat-holing, segregation and degradation.

![]() Fast recipe changeover

Fast recipe changeover

for agile manufacturing

![]() Prevent mix segregation

Prevent mix segregation

for a high quality product

![]() Trace allergens

Trace allergens

for accurate labelling

![]() Prevent bridging

Prevent bridging

for precise dosing

![]() Reduce cleaning times

Reduce cleaning times

for high efficiency & a better ROI

![]() Prevent cross-contamination

Prevent cross-contamination

for QA and consumer safety

Keeping dry ingredients contained is vital for beverage drink industry manufacturers that use 'free-flowing' powders.

Matcon has years of experience from working within the food, drink and beverage sector therefore we understand the importance of complying with strict food safety, hygiene and nutritional regulatory standards such as FDA Food Safety Modernisation Act (FSMA), Good Manufacturing Practices (GMP) and European Hygienic Engineering & Design Group (EHEDG).

We have supplied flexible and efficient production systems to numerous companies around the world making a wide variety of instant beverage mixes including 3 in 1 coffee, tea blends and powdered drink mixes. Our IBC systems have enabled our customers to increase productivity, reduce costs and improve product quality.

If you are mixing beverages for the sports nutrition industry, visit our page for sports supplement manufacturers.

6x faster production

with increased flexibility and food certifications.

Read Case Study

Improved product quality

weekly with rapid changeovers and flexible processing.

Read Case Study

1 hour per recipe

saved with dust-free processing and rapid changeovers.

Read Case Study

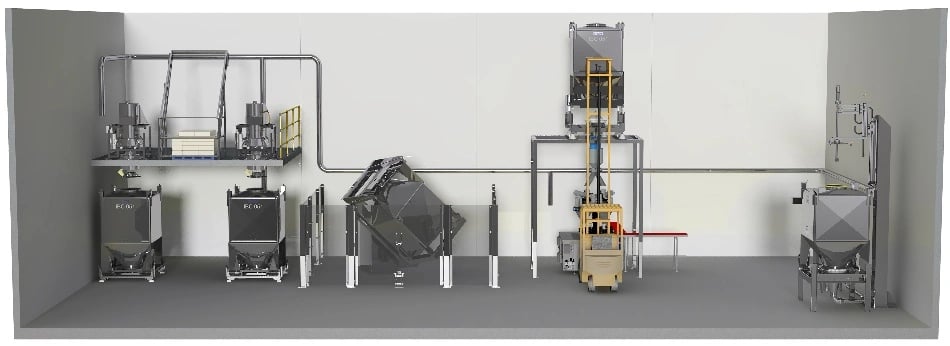

SYSTEM MODULES

Powder Handling Systems for Beverage Manufacturers

This simple system is all you need to get started the right way. By decoupling the processing steps we enable companies to achieve a flexible manufacturing system.

The Matcon system is based on using Intermediate Bulk Containers (IBCs) to transport powders between manufacturing steps and as a blending vessel. Because everything is contained within the IBC, there is no clean-down of the blender between recipe changes, which gives you the ultimate flexibility of operation.

LEARN MORE

Resources and Information

Equipment guidance and useful information for manufacturers of beverage mixes and powder based drinks.

- 5 Ways to Future-proof Your Food and Beverage Production

- Beverage Manufacturers Increase ROI With IBC Blending

- Case Study: Wetra Coffee 3-1 Coffee Mixes Manufacturer

- Case Study: Boh Tea - Beverages

- Case Study: Multitech Foods

- Resolving Ratholing for Beverage Powders

- How to Prevent Bridging and Arching Problems