INDUSTRIES

Equipment for Vegan and Plant-Based Meat Manufacturing

We provide powder handling and mixing equipment for manufacturers of vegan and plant-based products.

INCREASING PRODUCTION CAPACITY

for vegan and plant-based meat manufacturers

An IBC System will help you increase production efficiency of your plant-based foods from the moment you get started. With each of the key processing steps (formulation, mixing, packing and cleaning) being decoupled, manufacturing options become more flexible for your vegan and plant-based food production line.

YOUR CHALLENGES

Mixing challenges for vegan and plant-based meat manufacturers

An increase in diverse recipes and ingredients means that manufacturers of plant-based meat and vegan products are using difficult to flow powders such as pea and lupine protein with spice mixes which can easily segregate or cause blockages.

Many of the recipes used in vegan and plant-based meat products require a pre-mix to be dosed to an extruder. Poorly mixed ingredients and segregation during the movement of materials can lead to poor product integrity and wasted product.

Recipes need to be blended and transferred efficiently without risk of cross-contamination, which can result in extra time being spent carrying out thorough clean-downs between batches.

HOW WE CAN HELP

Improve vegan and plant-based meat manufacturers productivity

Our unique Cone Valve Technology, fundamental to each recipe batch IBC, protects your blended powders during the discharge process. Difficult to flow powders can be handled without the risk of segregation or blockages associated with big bags or pneumatic conveying.

Cone Valve technology provides consistent & controlled discharge which can match the optimal feed rates to extruders without the need for aggressive vibration. This means products keep their integrity and quality whilst being fed to downstream processes.

Blending using an IBC means that you spend less time cleaning and significantly reduce the risk of cross-contamination across your product lines as all powders are kept within the IBC.

OUR EXPERIENCE

Solving material processing challenges for manufacturers

The Matcon team have experience of working across the globe with a wide range of products manufactured by national and multi-national manufacturers of plant-based meat substitutes.

Our IBC System is proven to overcome the process challenges regularly faced in plant-based food production, to increase productivity, reduce costs and improve product quality.

So how do we do this?

OUR APPROACH

Working with vegan and plant-based meat manufacturers

Texturized vegetable protein (TVP), commonly referred to as textured soy protein or soy meat, high moisture meat analogues (HMMA) and meat substitutes consist of many different food ingredients, with several suffering from particle separation and being prone to stickiness, consequently disrupting material flow.

Central to our IBC technology is the Cone Valve, offering automatic and controlled discharge of virtually any powder type. Cohesive materials are stimulated to flow, whilst free-flowing powders are controlled. Our Cone Valve has continually proven to overcome the traditional powder handling issues of bridging, rat-holing, segregation and degradation.

The modular design of our IBC powder handling systems can be easily expanded as you innovate and grow your product portfolios and increase throughput to develop your business.

SYSTEM MODULES

Powder Handling Systems for Plant Based Food Manufacturing

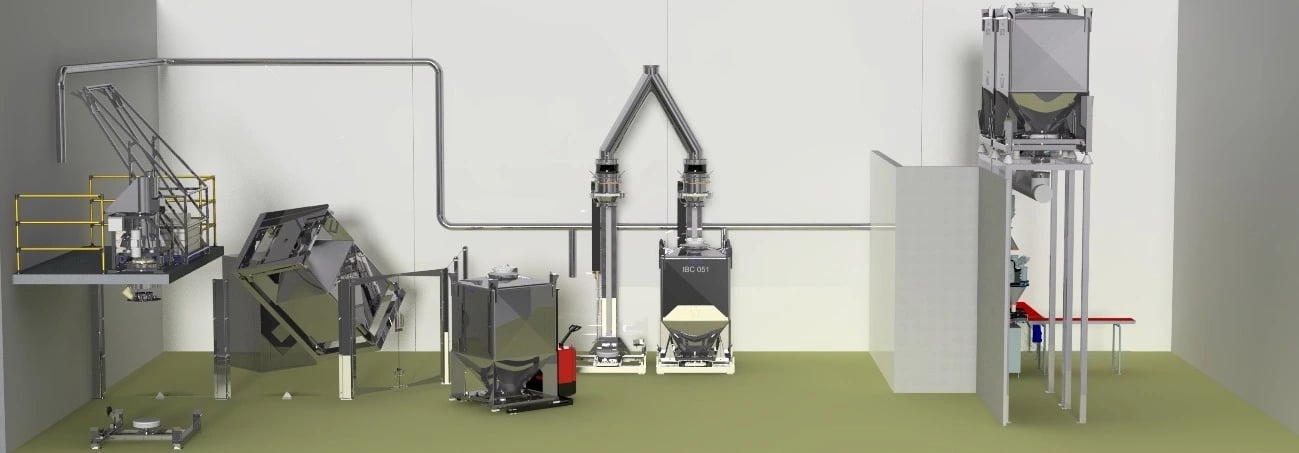

This simple system is all you need to get started the right way. By decoupling the processing steps we enable companies to achieve a flexible manufacturing system.

The Matcon system is based on using Intermediate Bulk Containers (IBCs) to transport powders between manufacturing steps and as a blending vessel. Because everything is contained within the IBC, there is no clean-down of the blender between recipe changes, which gives you the ultimate flexibility of operation.

LEARN MORE

Resources and Information

Equipment guidance and useful information for manufacturers of plant based food products.