CLEAN, FAST, RELIABLE

Powder Packing Modules

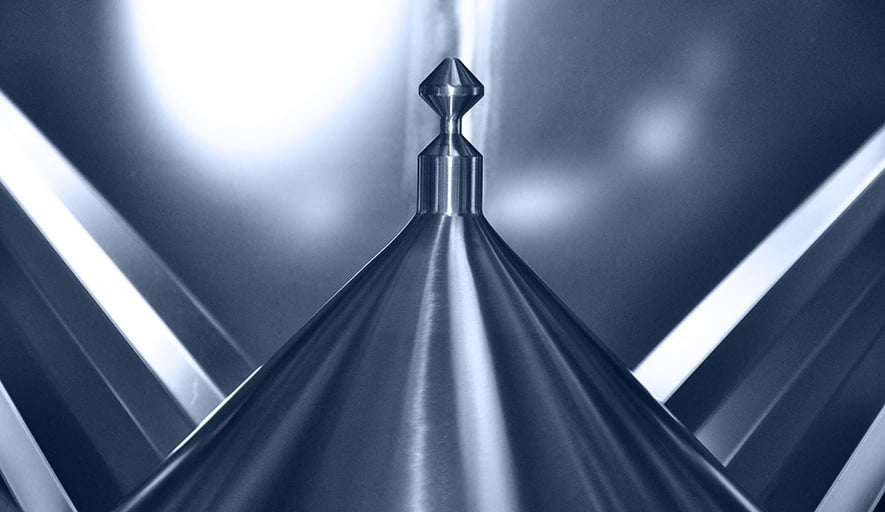

Achieve superior product quality by packing off without mix segregation.

Feeding to packing lines & filling sacks is automated, controlled and maintains product mix.

Cone Valve technology within each IBC delivers right first time, top-quality product.

Powder Handling System Modules

Matcon's packing modules are just one element of our efficient powder handling systems. Our processing equipment helps you at every stage of your powder handling process, streamlining your operations, improving product quality and helping increase your margins. By decoupling the manufacturing steps, we enable manufacturers to achieve a flexible and efficient powder handling system.

PROVEN CAPABILITIES

Global Testing Facilities

At Matcon, we want to ensure you have access to the right equipment and specifications you need to produce a high-quality end product. Materials, environment, humidity and powder characteristics all play a huge part in influencing how powders will behave during blending, packing or even in transit. Our state-of-the-art test plants give you the opportunity to test your product mixes with our equipment in a controlled environment.

Test Centres

Our state-of-the-art Test Plants are designed to simulate actual working conditions using your individual recipes, giving you peace of mind that your test results represent real world operations.

United Kingdom

Full-scale equipment capabilities including Near-Infrared (NIR) spectroscopy, allergen swabbing & lab testing equipment.

USA

Full-scale equipment capabilities including blending, formulation & cleaning.

China

Full-scale equipment capabilities including blending, formulation & cleaning.