20 February 2025

The cleaning of equipment and production facilities is an essential task for..

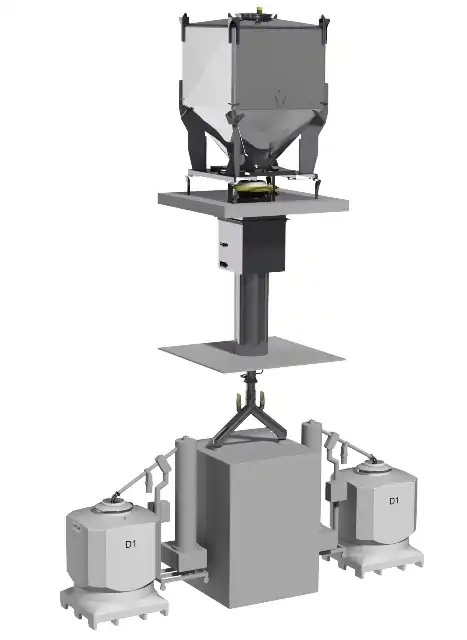

The right solution in the processing, storage and transportation of bulk material solids, powder, granules and tablets.

30 Min Read Time

In a competitive marketplace, you need to manufacture multiple batches effectively and keep up with demand safely.

The success of a manufacturer is dependent on their ability to produce a product as efficiently and cost-effectively as possible.

To achieve this, a production line must have the capacity and flexibility to meet the demands of today's consumer, whilst incurring minimal overheads associated with downtime and scrapped product. This is where an IBC system comes in.

With the potential to manufacture more than one product at any given time, IBC systems are pivotal in improving the efficiency and profitability of manufacturing companies worldwide.

This is why investing in an IBC system to manage and process your powders is vital to ensuring that you can meet demand and maintain your competitive edge.

Do some of your recipes suffer from segregation?

Is it a challenge when discharging some of your mixtures?

Are you losing valuable product unnecessarily down the drain?

Problems often occur due to inadequate or unsuitable equipment and errors due to manual intervention or operations. These can lead to issues in areas such as segregation of blended material, lack of containment or reduced/no flow of powder from a container. In worse case scenarios, this could result in a cease in production while the problem is being fixed.

Compared to butterfly valve IBCs, the Cone Valve provides superior discharge control, preventing the traditional powder handling issues such as bridging, rat-holing and blend segregation.

One of the best solutions for feeding powders or granules to a downstream process is an IBC. But not all IBCs are created equally and it's important to know what to look for.

What initially looks like a cheaper option is usually cheaper for a reason and may not give you the performance you need. It is worth researching to understand the benefits and limitations of different types of IBC. As well as production quality, the key difference in systems is in the valve outlet itself. Some manufacturers opt for IBCs fitted with a butterfly valve, others supply IBCs with cone valves.

Bridging, rat-holing, and blend segregation. These will be terms that you are all too familiar with, but what steps can you take to mitigate these issues?

Learn more about Matcon Cone Valve technology and how Cone Valves are the optimum solution for manufacturers processing anything from cohesive to free-flowing powders.

The unique Matcon range of Cone Valve technology within every IBC prevents the traditional powder handling issues such as bridging, blockages, segregation, flushing and core-flow.

Better understand the Matcon range of IBCs:

Find out which IBC is right for your powder handling requirements.

Matcon's powder handling equipment allows you to reduce overproduction and waste, safely transport materials with cross-contamination and improve the effectiveness of your operations.

By decoupling each of the key powder processing stages, these can all take place simultaneously 'in parallel'. This means that your production facility can embrace lean manufacturing and become more efficient. Learn more about Matcon's powder handling equipment.

Explore the highly effective blending of powder with quick cleaning in between batches - achieve high OEE rates with an IBC Industrial Mixer.

The simple design of Matcon's powder packing equipment ensures that manufacturers reduce downtime as change-out parts can be quickly cleaned off-line. Undertake recipe changeovers in minutes not hours.

How can you ensure you ask all the right questions when selecting an IBC supplier?

The Matcon Ideal IBC System checklist will help you ask the correct questions of your IBC supplier.

With the support of the guide, you will solve your powder handling problems and validate your equipment procurement process.

What are the full benefits of a decoupled system?

Efficiency and overheads are two major factors that manufacturers strive to influence on their production lines. The ability to improve these are pivotal to the success of a company, which is why choosing a powder handling system that addresses these areas of concern is so vital.

A manufacturer must be efficient, productive and profitable; and so too should their manufacturing process. This is where a decoupled Intermediate Bulk Container (IBC) system comes in.

We explain what a decoupled IBC system is, and why it is better.

Avoid damaging equipment and stock with the correct manufacturing methods.

In addition to 'Bin-rash', we've also seen operators fully clothed in hazard suits rodding the product through the container inlet in an attempt to discharge product.

These issues can be avoided completely when you've got the right powder discharge device.

Find out how to get better powder flow with Cone Valve technology.

Read our pharmaceutical blog to learn more about powder and tablet handling best practice.

Have you ever calculated how much valuable time is lost because of that or the damage it does to the powder and equipment, not to mention the GMP risks involved!

It is not accurately known what capacity of valuable powder ingredients are lost each year, simply caused by loss of blend uniformity or regular manual intervention during the manufacturing cycle.

These costly issues can be reduced significantly by selecting the appropriate powder handling system. Read our blog on reducing your cost per kilo to identify the root cause of your problem and discover the solutions available to solve them.

Read our blogs on IBC systems for powder handling.

Manufacturing success hinges on efficiency and cost control. Matcon's IBC systems are designed to solve your toughest production challenges—streamlining processes, cutting waste, and improving overall performance.

Want to stay competitive? Contact our team today for expert guidance and a solution built to fit your needs.

At the heart of the Matcon system you will find the Cone Valve - invented, patented and developed by us. We help manufacturers overcome issues of mix segregation, containment and bridging that are inherent in traditional powder handling systems. Discover our unique approach to powder handling and the innovation that underpins all that we do.

About us