When changing your powder process equipment from fixed mixers and in-line conveying systems to using a decoupled processing solution, the choice is often between using Intermediate Bulk Containers (IBCs) or Big Bags.

Powder IBCs or FIBC Bulk Bags - which is most suitable?

At first, sight, keeping the initial CAPEX costs down may seem the most attractive option. But is this the correct measure of suitability? What about the real ongoing cost of operating the system?

What are the advantages of using Big Bags for Powder Handling?

- Lower capital cost

- Low packaging weight - lighter to ship

- Easy storage of empty bags

- One-way transportation

- No cleaning as bags are disposable

- No contamination risk due to single-use

- Familiar as being utilized for raw materials

The Disadvantages of using Big Bags for Powders

- Ongoing cost to replace used bags

- Dusty operation exposes a contamination risk

- Limited control over the discharge of contents

- Risk of segregation of blends

- Environmental charges for disposal

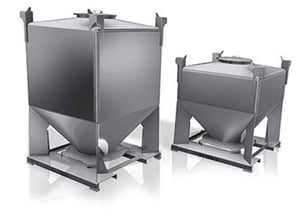

What are the advantages of using Intermediate Bulk Containers (IBCs) for Powders?

- IBCs are fully contained for dust-free handling

- Controlled & automatic discharge of powder flow

- Full & partial discharge achievable

- No segregation of blend

- The IBC becomes the blending vessel permitting fast recipe changeovers

- Easy-clean, hygienic design

- Low operating costs

- Available in a variety of sizes between 300 and 3100 litres

Disadvantages of using Intermediate Bulk Containers (IBCs) for Powder Handling

- Higher initial CAPEX expenditure

- Not economical for site-to-site transfer

- Storage & logistics constraints

Often the initial capital investment alone favours the selection of the Big Bags however have you considered their lifetime cost? What conclusion do you draw if you consider the following in your cost calculation:

- Expenditure on bag replacement

- Cost of bag disposal

- Yield losses

- Number of unit movements

- Labour requirements for making/breaking connections

Powder Handling Sytems and Equipment

The Matcon team has decades of experience working in the bulk powder industry and developing powder handling equipment. If you would like to discuss the use of IBCs in powder handling or would like to have a system that meets the highest hygiene and safety requirements, then please get in touch.

Posted by

Matt Baumber