The issues associated with traditional powder handling systems, and the benefits of investing in an IBC Powder and Bulk Solids System as an alternative, are clear. However, identifying an IBC system that will provide you with the improved efficiency and product control that is required, necessitates detailed technical review.

As with any machinery, not all IBCs are designed equally, and it’s imperative to identify inadequate technology early on in your buying process to help guide your investment.

Inadequate IBC technology

IBC systems have the potential to provide superior powder handling abilities over those offered by traditional coupled systems, but not all of them are free from the issues associated with manufacturing powder-based products. To identify these ineffective systems, it’s important to carry out an extensive research and comparison process, which should highlight the significant performance differences between each system. Issues to look out for during this process include:

Poor product flow

This often results in the need for manual intervention, maybe hammering the outside of the IBC to promote powder flow which results in hammer rash and the likelihood of increased scrappage.

Recipe segregation

This can cause poor quality product, as each consumer unit won't contain the correct ratio of ingredients, again increasing the need to scrap product.

Uncontrolled product flow

An inability to control the flow of your product at the packing phase, will inevitably see you flooding the packing machine, incurring costly downtime and production delays. Or no product flow which results in stoppages whilst the blockage is released.

Unsuccessful cleaning modules

If an IBC system is difficult to clean, containers may not be properly disinfected between batches, resulting in contaminated products. This is particularly concerning if you are working with allergens.

The issues that can arise from investing in inadequate technology, will easily cancel out any of the lean benefits that come with a decoupled system. If you don’t take the time to meticulously investigate and identify a system that is able to address all of your powder handling issues, you put yourself at risk of investing in a system that has the potential to cause further problems in your manufacturing process.

The Matcon IBC System

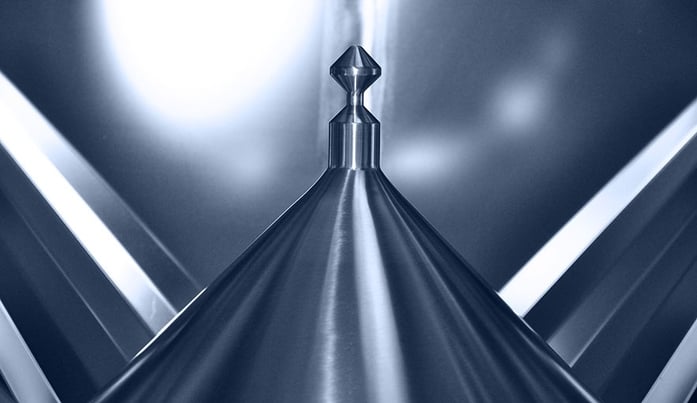

Matcon’s IBC System has been designed and developed to overcome all of the problems associated with powder handling. Originally patented and designed by us, each Matcon IBC has our Cone Valve technology at its heart, which has been proven to overcome even the most challenging of issues.

This unique technology works to address the issues associated with powder handling, such as:

- Product flow – integral Cone Valve vibration and variable lift height ensure full control over product flow, without the need for additional feeders. Free-flowing materials can be controlled with small lift heights or sticky materials can be prompted to flow.

- Segregation – the unique Cone Valve technology encourages the powder to move under mass-flow by holding back the powder in the centre of the IBC and stimulating flow from the sides, so that material discharges as first in, first out thereby maintaining the integrity of the mix and preventing segregation or demixing.

- Cleaning – the simple design of the IBC makes it easy to clean, resulting in minimal risk of cross-contamination or bacterial build up. This reduces the costly risk of product scrappage.

In addition, this technology has been proven by world leading manufacturers to greatly improve output as multiple batches can be produced simultaneously. Ensuring that products can be manufactured in a controlled and efficient environment enables you to make the most out of your production line.

Choosing an IBC

As is true of most technology, there are companies, other than Matcon, that produce an IBC system that uses ‘Cone Valves’. These systems will vary in performance and price, just as all IBC systems do. Therefore, if you are tempted by an alternative ‘Cone Valve’ option, it’s important to still carry out due diligence and assess whether the system meets your requirements – a cheaper option may save you money now, but is often a costly choice that results in further expenditure down the line, far greater than what you stand to save in the present.

Another factor to consider when purchasing is how to apply the technology to your processes – even great systems can come undone when not installed optimally. This is where Matcon sets itself apart.

We offer full-scale Test Centres where you can take your own powders, to test whether the system will work for you, before you invest. This way, we can work with you to solve your powder handling issues, and ensure that, if you do decide to invest in the Matcon IBC system, we can install your apparatus to provide maximum efficiency and profitability.

Topics:

IBC System