As consumer demands are continually changing, manufacturers must have flexible and efficient production processes to stay ahead of their competition.

Until now, if a powder blend required liquid addition, it was necessary to use a Fixed Mixer, which can be difficult and time-consuming to clean between recipe changeovers, leading to large amounts of downtime.

Add liquids during powder blending

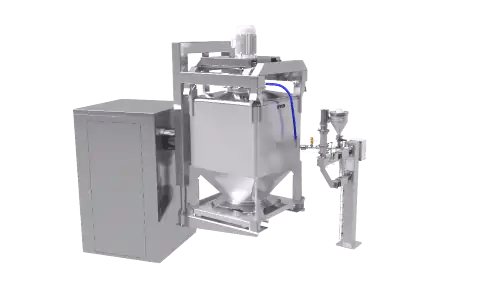

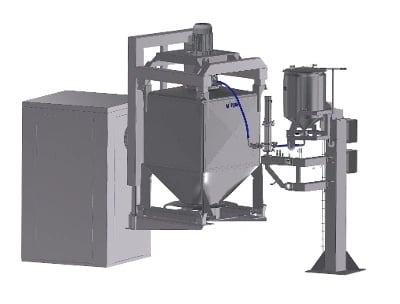

Invented and developed by Matcon, our innovative Liquid Addition System (patent pending) expands the range of the IBC tumble blender and is well suited to industries that need the flexibility to add liquids into a wide range of powder recipe mixes in a contained and efficient manner.

The system works by automatically injecting, on each blend rotation, one controlled liquid ‘shot’ directly into the powder mix inside the Matcon Intermediate Bulk Container. This removes the need for manual intervention or opening of the blending vessel. The high shear intensifier on the IBC lid ensures the even dispersion of liquids within your powder recipe during the mixing process and prevents lumps from forming.

Designed for manufacturers that need to deliver additions of liquids to a dry powder blend, the system has two options:

- Low Volume Liquid Addition with a range of 1- 10 litres

- High Volume Liquid Addition, delivering a range of 5-150 litres.

This flexible and hygienic liquid addition system reduces manual handling requirements within the process and improves containment, further enhancing the benefits of IBC Blending.

Liquid addition for powder blending - without the lumps

The system consists of a free-standing pillar supporting the liquid holding tank (two size options are available), a reciprocating pump and weight monitoring system. These are connected using tri-clamped hoses and a rotary coupling, to the injection nozzle mounted on the IBC lid adjacent to the Matcon Liquid Additions Intensifier. As the blender rotates the IBC, the liquid is injected into the IBC with each rotation. The high shear intensifier ensures that it is all fully integrated & mixed.

To minimize the downtime for cleaning, operators can swap out parts quickly without the need for additional tooling, thereby keeping the blender in production, further improving the efficiency and throughput of a production facility. The system also includes CIP flushing using neutral oils or cleaning fluids.

Reduce manual handling and contamination risk

Matcon's Liquid Addition is a flexible and hygienic system that enables batch-based blending, reducing manual handling, and improving containment levels. This functionality ensures that manufacturers across a range of industries can further enhance their IBC Tumble Blending process.

Key advantages of Liquid Addition:

- Rapid integration of liquid into a powder blend through high-shear mixing.

- Injection directly into powder mass at Intensifier blade tip, while tumble blending, no need to open the container.

- No longer a requirement for two-stage blending.

- Maintain high containment levels as liquids are injected during blending.

- Controlled liquid 'shot' for accurate dispersion.

- Pre-programable recipes for ease of use.

- Change-out parts are easily cleaned ‘offline’ keeping the blender in production.

- Loss-in-weight monitoring on the liquid tank guides the blending stages.

- No loss of liquid on vessel walls.

A comparison of features for Low and High Volume Liquid Addition

| Feature | Low Volume System | High Volume System |

| Addition volume | 1 - 10l | 5 - 150l |

| Vessel (liquid bottle) options | 5l / 10l | 150 l |

| Liquid shot volume range (per revolution) | 100 - 500ml | 200 - 800ml |

| Column height (inc vessel) | 2m | 3.1m |

| Liquid viscosity capability | Up to ~56mPa.s | Up to ~56mPa.s |

IBC Tumble Blending - learn more

To find out more about our developments in IBC Tumble Blending technology and how to expand the capabilities of your powder processing, please download the brochure via the link below.

Posted by

Matt BaumberTopics:

Blending