Consumers in the Sports Nutrition and Nutraceuticals sector are becoming ever more demanding. Sometimes you don't get a second chance to delight them. If you're produce is sub-standard, or out of stock, you risk losing them.

How can you create a manufacturing system that gives you the agility to react to market demand? It's critical in today’s world of FMCG products, and probably even more so in the Sports Nutrition market where it is vital to have your product

available ‘on-shelf’ when customers are buying. If you miss that opportunity to satisfy their need, will you be able to win them back?

If your supplement manufacturing system is based on fixed mixers how easy is it to swap over recipe production? I’m guessing that it takes a good couple of hours to conduct a thorough clean-down. To overcome this wait, many companies conduct a ‘white to black’ system of production or campaign manufacture in an attempt to improve efficiencies. However this only results in expensive inventory or WIP - a burden on the working capital KPIs that often ends up in on-costs as warehousing space needs to be expanded.

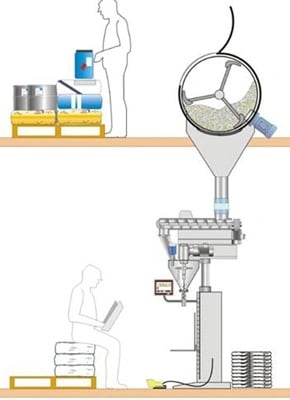

IBC Material Handling

Have you ever considered what an IBC system could do for you? By both handling and processing your powders in individual containers you have total production flexibility. Cleaning times are significantly reduced to minutes instead of hours. Blending recipes within the container itself means that there isn’t any need to clean the blender between batches, so any recipe can be made at any time - a very lean, agile solution to an age-old problem.

Read more about Matcon IBC powder handling systems and to speak to a member of our team please contact us.