Matcon has 40+ years of experience in handling powders for manufacturers, working across a range of industries from food flavorings and production to pharmaceuticals. Throughout this time, we have encountered innumerable problems which were solved using a combination of industry know-how and innovative thinking by our in-house experts.

Before implementing any of our suggested solutions, we give companies the opportunity to test those powder-handling solutions for themselves in our test plant. By providing the ability for manufacturers to test the solutions beforehand with their own products, an informed decision can be reached before outlay of expenditure on new equipment.

In this article, we will cover some of the most common issues we see in food processing plants and how they can be solved.

Close-Coupled Mixer Layout

This problem can be one of the unknown issues in food manufacturing. Fixed line conveying of powders might seem cheaper in terms of equipment, but the costs often come later in the form of lost time or safety risks, especially when recipe changeovers are required.

In a close-coupled system such as a fixed-line pneumatic conveying system, the cleaning process becomes much more complex. To perform a full clean, the entire processing line must be stopped, taken apart, cleaned and dried (if wet washed).

A stricter regulatory environment demands that cleaning be carried out to a very high standard, thereby adding time to the procedure.

Matcon's powder handling systems offer the solution to this as the entire line can be designed in a decoupled fashion, thereby allowing for better batch control and more efficient processing as IBCs can easily be changed or cleaned offline. This means that food manufacturers have more time to perform other tasks.

Poor control of powders

Food manufacturers need to pay particular attention to the control of powders throughout the production lines to remove safety risks, such as allergen cross contamination.

For example, using the same line to manufacture gluten containing recipes and gluten free can lead to ingredient cross contamination, even if the line is washed between recipes.

Food processing plants also have to consider cross-contamination risks through factors such as:

- airborne dust,

- ingredients escaping during discharge

- remaining powder residue in equipment

- poor cleaning methods.

If a container is not made of the correct material or given the required finish, powders are more likely to adhere to its internal surface, further risking contamination of formulae and mixtures when it is used for another recipe batch.

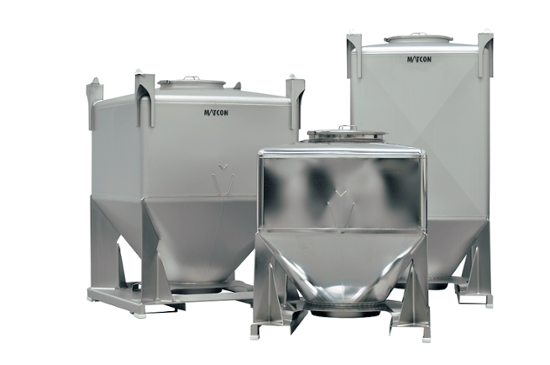

This problem is solved completely by using state-of-the-art Matcon Stainless Steel IBCs for food processing as each is manufactured with no enclosed crevices or hollow sections that could trap product or contaminants.

Human error resulting in wasted product

Although not common, we have seen examples of human error resulting in the incorrect product or amount of ingredient being fed into the equipment at the formulation stage.

This can result in significant production downtime as the system will have to be cleaned thoroughly, with the product removed entirely to prevent cross-contamination.

The best way to deal with this is to introduce automated procedures for the feeding of product into containers, such as the use of barcodes on each IBC with the correct recipe ingredient details.

How Matcon’s IBCs resolve all these issues completely

Matcon IBCs are designed to meet the highest food hygiene standards. The IBCs have no enclosed crevices or corners, preventing the build-up of product, which could lead to cross-contamination or the presence of allergens.

The IBCs are fully self-contained, preventing contamination from airborne dust.

In addition, the IBCs make use of our unique Cone Valve technology to ensure that powder does not segregate or suffer from the all-too-common problem of “rat-holing”, as is often the result of using butterfly valves or slide valves.

The configuration of the IBCs is entirely decoupled, so there is no time lost while product mixes are changed, or one IBC is taken off-line for cleaning.

That cleaning procedure itself is relatively easy compared to other containers which have not been designed to such rigorous standards.

Furthermore, because the IBCs are interchangeable, there is no risk of mixing your powder products because each recipe is kept in a self-contained IBC.

The varying range of IBC sizes allows for make-to-order batches as well as much larger loads.

Multiple Problems, One Solution

Indeed, every single one of the problems we identified above is resolved by our IBC system and the revolutionary Cone Valve technology inside each IBC.

To conclude, our extensive experience gained throughout our history has developed a system which is highly efficient in reducing common food manufacturing problems. To learn more, please visit our Matcon IBCs page here.

Posted by

Matt Baumber