31 January 2025

Since our foundation in 1980, Matcon has built a world-renowned reputation as..

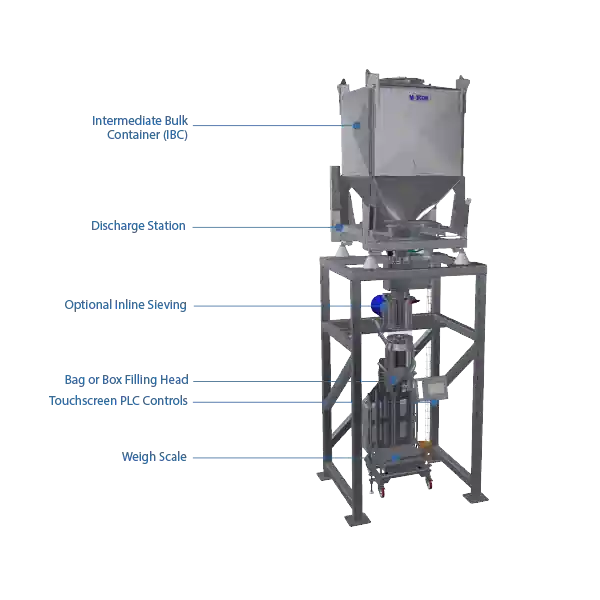

Powders can be directly discharged straight from the IBC into sacks faster than alternative auger fillers & with dosing accuracy.

Packing capacities from 10 to 25kg sacks, with the ability to pack off 1-2 bags per minute.

Cone Valve technology inside the IBC protects the powder mix ensuring no segregation for a high-quality final product.

Dosing accuracy from Cone Valve technology, combined with LIW & GIW load cells

Fast batch changeovers with simple changeout parts & tool-free connections

Handles free-flowing & cohesive powders without changing parts

In-line sifting optional

Store multiple recipes in simple to use control panel

Fast clean down