When you take sports nutrition as seriously as your customers, producing the perfect blend of evenly mixed ingredients is key. As you scale production, delivering different volumes at cost-effective speeds, whilst maintaining quality, can be a challenge. How can you ensure quality every time? What technology exists to help you consistently achieve a flawless blend in sports nutrition manufacture?

Consistently Delivering for Your Customers

To ensure consumer loyalty, you can’t afford to gamble on the condition of your end-product.

In an industry where consumers emphasize looking and feeling good, the appearance and mouth-feel of your products are paramount. Segregated thickening agents can result in an extra-thick protein shake one day and a runny one the next, which reduces customer confidence in your product.

Increasingly wised-up consumers want to be certain they’re getting the macro and micro-nutrients they need. Blending your product effectively and ensuring it is packed off correctly without segregation is the only way to ensure they receive the measured doses of the vitamins, minerals and nutrition you promise on the label.

Producing Exactly What It Says on the Tin

Under the Food Safety Act, it is an offense to sell food - including sports nutrition products - that do not meet the description on your label. Responsibility for accurately labeling products falls to you, the sports nutrition manufacturer.

The only way to deliver your advertised nutrient profile, in every hundred grams, scoop or portion, is to ensure that the correct quantity of ingredients were used, they were consistently blended and then reliably transferred into the consumer pack/SKU.

Making sure it’s right from the start

If you don’t put the right ingredients in at the beginning, no amount of careful processing thereafter will rectify the situation. Sizing batches such that full sacks can be tipped is a good idea to cut down on the risk of error in weighing and measuring. Creating bigger batches of pre-mix and dispensing measured doses into each batch not only reduces the manpower needed to make each weighment, but also reduces risk of human error. Further checks and balances can be put in place using barcoding and RFID readers feeding MES systems ensuring the correct batches are being assembled.

Don’t stir it up too much

Did you know that within the mixer a batch can become mixed  then separate again if you over process it? Ensuring the optimum blend time is a science in itself. We have been researching NIR (Near Infra-Red) technology as a way of measuring the exact point at which a batch is mixed.

then separate again if you over process it? Ensuring the optimum blend time is a science in itself. We have been researching NIR (Near Infra-Red) technology as a way of measuring the exact point at which a batch is mixed.

This miniature technology is small yet powerful, using near infra-red spectroscopy, the NIR displays real-time blend consistency data on every rotation. This ultimately reduces blending time and prevents over-mixing. It also removes the need for product sampling which saves time and reduces the risk of sampling errors.

Invest in peace of mind

With traditional fixed mixers, whilst they may efficiently mix the ingredients, they can be prone to suffering from segregating the mix on transfer. If there is a long drop to the receiving container the ingredient ‘fines’ can get separated out. Or if pneumatic conveying is used, unless carefully monitored, degradation can occur.

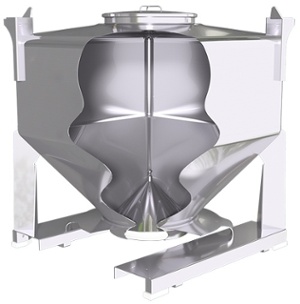

IBC Blending removes one of the transfer steps as product is blended in the IBC which is then transported directly to packing. But here we advise caution as butterfly and slide valve bins can lead to core flow and particle rolling, which will de-mix the blend, which may then have to be scrapped or reworked.

Matcon’s IBCs contain Cone Valve technology which comprises a ‘passive’ cone seated in the outlet of the container. When raised by the Discharge Station an annular (circular) gap is created which causes powder to flow under ‘mass-flow’ discharge, meaning that all the material moves down the container as one. This removes the occurrence of particle rolling and creates FIFO (first in, first out) emptying of the vessel so the carefully blended mix remains homogeneous throughout the discharge process. Delivering a quality material from beginning to end.

In addition the design of the bins in combination with the Cone Valve prevents product sticking to the side of the bins and encourages it to flow and discharge completely.

The rising and vibrating action of the cone also loosens or breaks up and moves sticky materials, which are common problems when handling protein powders.

Investing in the right technology for your sports nutrition manufacture not only gives you assured product quality, and brand security, but also can save you time and reduce waste, ultimately improving your returns. To see how Matcon’s technology could help you grow your business, use our ROI calculator to perform a cost-benefit analysis for your business.

%20(1).webp?width=600&height=100&name=SportsNutrition-Production%20(1)%20(1).webp)