Using one of Matcon’s test plants, customers are able to mimic pilot testing by having equipment available that permits product trials across all stages of powder processing. Any powders and combinations can be put to the test to prove the equipment’s suitability to manufacture either single or multiple batches of product. In addition to having the opportunity to test the equipment with your own product materials, you will also gain insight into Matcon’s philosophy and solutions for more efficient, faster and cleaner production.

Once you’ve completed your product trial and experimented with your products in one of our fully-equipped test plants, you’ll have gained a greater understanding of your ingredients. You’ll also confidently reduce processing times and maintain the highest standards in product manufacturing.

You can now work with Matcon to perform equipment trials, complete powder analysis or do more thorough R&D testing. You may just want to carry out equipment demonstrations or facilitate operator or engineer training. In any case, full data reporting from the tests will validate and strengthen your business case for improvements to your powder processing workflows.

What operations and activities do customers trial in the Matcon test plant?

Matcon’s powder handling test plants allow customers to complete thorough evaluations with their own products and the opportunity to test different processes and combinations of equipment for the best results possible.

During testing, customers can undergo:

- Product and ingredient testing

- Powder Analysis

- Equipment demonstrations and personnel training

All our state-of-the-art test plants are equipped with full-scale materials handling equipment which replicate working conditions for production-oriented interface testing. In the UK, Near Infrared Reflectance (NIR) spectroscopy is used to prove homogeneity and determine correct recipe blend times, removing the need for invasive sampling. Allergen and ATP swab testing is also available to prove cleaning capabilities.

Testing your own powders and materials

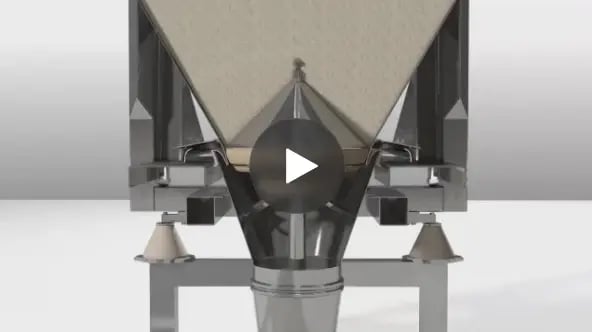

Using a Matcon test facility will give customers the opportunity to mimic pilot testing by having equipment available that permits product trials across all process stages. The team at Matcon use laboratory equipment to assist customers in the analysis of material properties such as bulk density, angle of repose, flowability, drying properties and particle sizes. Our experienced process engineers use these test results to create a detailed view of the product and define the key operating parameters and equipment settings required to handle and process the materials correctly. Our team can help define the following:

- Dispersal and homogeneity

- Powder layering

- Blending performance

- Prevention of segregation on discharge

- Accuracy and speed of dosing/packing performance

- Levels of containment

- Material flow and discharge capability

- Cleaning capabilities for both wet wash and air wash

- Gentle tablet handling

- System interface/integration

- Weighing and packing accuracy

- Throughput and production capacity

- Faster equipment cleaning reducing down-time

Typical test parameters and results by industry

Below are some scenarios that have been tested during customer trials at Matcon’s test plants.

Bakery

Requirement: To test the use of Liquid Addition during the tumble blending process.

Customer Issue: Chopping solid fats into a powder mixture. Solid fat did not disperse during the blending process and caused balling (when powders stick in very small balls).

Solution Tested: Liquid addition provided an even dispersal of liquid fats with no balling. After visual examination and testing by the customer in their own test lab, and with Matcon's assistance, validation was achieved.

Food Flavourings

Requirement: To discover optimum blending times of a set recipe.

Customer Issue: Under or over mixing of ingredients created inconsistent batches and product wastage.

Solution Tested: Matcon's Tumble Blender - along with NIR - was demonstrated to measure the blending capabilities and confirm the optimum speed and blend time to achieve a perfect mix. An additional demonstration of the wet wash cleaning module and validation using an ATP monitor displayed exceptional cleaning performance after being taken offline and wet washed.

Sports Nutrition

Requirement: Improve flow of difficult-to-discharge powders. The range of powders included sticky materials and the customer was using butterfly valves at their facility.

Customer Issue: The butterfly valves caused bridging during ineffective powder flow, leading to segregation of the end product.

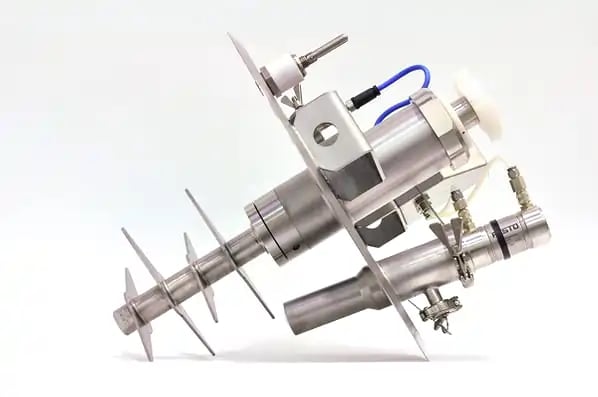

Solution Tested: The customer trialled their own powders using a Matcon IBC incorporating a Cone Valve. The Matcon IBC provided effective powder flow with no bridging or segregation issues.

General Food

Requirement 1: Accuracy of the packing station.

Customer Issue: The customer was previously experiencing variances in their batch quantities due to inaccurate dosing during the packing stage.

Solution Tested: Matcon’s Cone Valve provided consistent and accurate dosing at the powder packing station, ensuring every batch contained exactly the same quantity.

Requirement 2: To reduce levels of cross contamination from residue on equipment.

Customer Issue: The customer was losing profitability due to excessive time spent cleaning and re-cleaning equipment due to validation failures. Also, the drying of their equipment significantly reduced daily production levels.

Solution Tested: Cleaning tests were performed using Matcon’s air and wet washing systems. The equipment was validated to ensure no batch cross contamination occurred when IBCs were returned to production.

Beverages

Requirement 1: Formulation testing to determine the correct order in which to fill an IBC with ingredients.

Customer Issue: The customer sought guidance in product recipe formulation to manufacture the highest quality product.

Solution Tested: The correct recipe and order of ingredients was found and formulated ready for the customer to repeat in their own facility.

Requirement 2: Improvements in ingredients mixing processes.

Customer Issue: The customer was experiencing poor mixer performance and discharge capabilities and their product was segregating during discharge.

Solution Tested: Matcon's Cone Valve demonstrated how efficiently mixed product could be discharged without any segregation.

Chemical/Pigments

Requirement 1: The perfect mix at formulation stage.

Customer Issue: The customer previously experienced issues with variances in their batch sizes and the mix quality.

Solution Tested: A variety of different powders were layered at the formulation stage and tested to find the best mix combination. Matcon IBCs were used for mixing, containment and discharge.

Requirement 2: Identify if the Matcon IBC system would successfully handle a customer’s specific ingredients and formulation.

Customer Issue: The customer was disappointed with the performance of their previous equipment and needed to prove to their management team that a new system would be worth the capital investment.

Solution Tested: The customer was able to use their actual powder ingredients with Matcon IBCs to gain knowledge on the flow capabilities, characteristics and simulate discharge to rule out any potential flow issues.

Analytical pre-tests available by Matcon

In addition to thorough equipment solutions testing at Matcon test plants, customers can also gain insightful knowledge from the deep experience that the team at Matcon offers.

Our team can assist in the analysis of material properties such as bulk density, angle of repose, flowability, drying properties and particle sizes. Our experienced process engineers use these test results to create a detailed view of the product and define the key operating parameters and equipment settings required to handle and process the materials correctly.

Our expert team can help customers define:

- Loose bulk density

- Tapped bulk density

- Moisture levels

- Angle of repose

- Angle of slip

- De-aeration of powders

- The Carr index

- Hausner ratio

- Particle size distribution

- Sieve deck analysis

- NIR spectroscopy

To discuss how you can book time in one of our Matcon test plants, contact our sales engineers today.

Posted by

Matt Baumber