Ineffective production processes are the downfall of countless manufacturers. Often, equipment is unable to keep up with consumer demand due to capacity limitations, or regularly produces low quality product because of inadequacies in the machinery or process design.

Effective equipment is an essential asset for any manufacturer who wants to stay both competitive and productive, which is why world-leading manufacturers are increasingly switching to decoupled systems to improve their efficiencies.

What is OEE?

Overall Equipment Effectiveness (OEE) is a manufacturing metric that takes into account the separate processes of a production line. Your OEE is found by assessing the availability, performance and quality of a process line, and combining these assessments provides you with a percentage of effectiveness.

The outcome of carrying out this metric gives manufacturers a clear overview of their production processes and allows them to identify areas where improvements can be made.

Decoupled vs. coupled systems

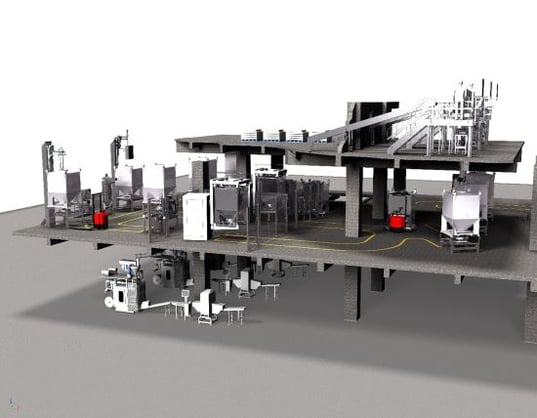

If a manufacturer has to produce a range of batch sizes and types, then the OEE of a decoupled system will be much improved, when compared with a coupled ''fixed lin' system. A decoupled Intermediate Bulk Container (IBC) system is based around the use of individual containers (IBCs) that house a recipe batch throughout the entirety of a manufacturing process.

These IBCs are moved from one process to the next, and work to address the issues associated with low OEE by:

Increasing flexible production - the intuitive and flexible nature of a decoupled system allows numerous batches to be manufactured simultaneously on the same production line. In contrast, a traditional coupled system is normally only able to produce one batch at a time as each process is fixed, and extensive cleaning is required between batches.

Reducing downtime at recipe changeover - as the recipe ingredients remain within a container throughout the whole manufacturing process, this eliminates the need for equipment cleaning between batches. For example, the blending process is achieved by loading the IBC into the IBC Tumble Blender, where the ingredients are mixed within the IBC itself, and then the IBC is simply removed and transported to the next phase of the production line. In contrast to a coupled system, each process is fixed, meaning that the ingredient mixes themselves are moved from one stage to the next, leaving behind residue that requires cleaning between batches.

Improving quality – As IBCs remain sealed throughout the whole manufacturing process, the risk of cross-contamination is almost entirely eliminated, leading to a reduction in product wastage and improved quality control. With a coupled system, mixes are often moved manually from process to process, exposing your product to a much increased risk of cross-contamination.

The OEE benefits of a decoupled system greatly outweigh those associated with a static coupled system. You can find out more about the value of a decoupled system over traditional coupled systems here.

The Matcon IBC System

The Matcon IBC System was designed to eliminate waste with flexible & agile powder handling, promoting lean manufacturing principles. The system encompasses all of the efficiency benefits associated with a decoupled system.

The unique Cone Valve technology which sits at the heart of the Matcon IBC overcomes even the most challenging of powder handling issues. The technology uses integral cone vibration to stimulate mass flow of ingredients by encouraging flow from the sides of the IBC. This improved product flow greatly reduces the risk of product segregation and bridging, resulting in a superior product with limited scrappage. As well as our patented Cone Valve technology, Matcon’s IBC system provides manufacturers with:

Simple powder formulation - IBCs are decoupled from the process which allows manufacturers to formulate and add mixes directly to a container whilst it is offline, eliminating the need for any other process equipment downtime.

Full powder control - the Cone Valve provides full control over powder flow during packing, ensuring that packing machines are not flooded, and the integrity of your product is consistent.

Effective cleaning process - cleaning of an IBC is quick and easy due to its simple design, and can be performed offline, without disrupting production.

The Matcon IBC System has been proven time and time again, by leading manufacturers, to improve their Overall Equipment Effectiveness (OEE) of their production process.

By investing in a decoupled Matcon System, you create the potential to greatly increase your OEE and improve your manufacturing capacity levels, to allow you to keep up with consumer demand and maintain a competitive edge in today’s market. You can discover more about the Matcon IBC System here.

Posted by

Matt BaumberTopics:

IBC System