If you're a battery manufacturer, then you know that The Battery Show Europe was the place to be this June. The event brought together the biggest names in the battery industry and provided a forum for discussing the latest advancements and technologies. This year, Matcon was delighted to meet and chat with guests at our stand in hall 10.

Our experts were on hand to answer any questions visitors had about our powder handling solutions. In this blog post, we'll share some of the most common questions our experts were asked at The Battery Show 2022!

What are the benefits of your dry-blend powder solution?

Matcon has been delivering powder handling systems for decades across a wide range of applications in the chemical, food and pharmaceutical sectors. What we learn in one sector can be appropriately applied to another challenge. We are used to designing systems that successfully manage highly challenging powders. We have experience in installing large-scale, complex formulation systems for those where the Matcon IBC system is just a small part of a very niche solution.

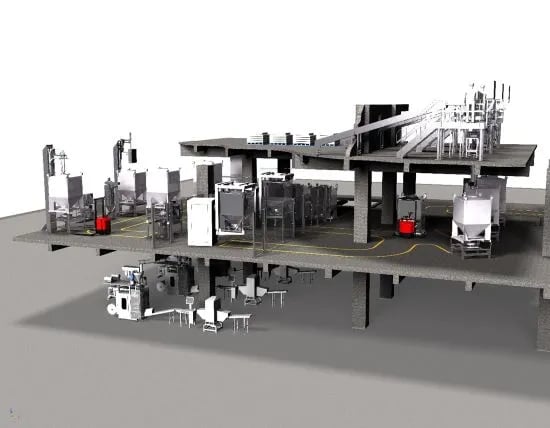

Our IBC system is very modular, and you can start small and build as you grow. We have experience integrating a variety of other equipment into our systems to create a full manufacturing system, which makes Matcon a true solution provider to the battery industry, meeting the needs of both cathode and anode manufacturers.

We have experience in delivering systems designed for safety, with all components meeting industry regulatory standards. The end result is a raw material handling system that is reliable, efficient, and safe for the operators at the site.

At the show, we heard how many customers are moving towards dry powder-based processing as it offers a number of benefits over traditional wet processes, including the elimination of solvents and associated drying processes and improved economic viability for large-scale Li-ion battery production.

Matcon’s IBC blending system is a key enabler for this new technology trend, as it delivers the desired particle size distributions and target homogeneity for dry blended ingredients. To meet the more challenging demands of the sector, we have an active research programme that is exploring how our existing high shear intensifier can be adapted to give just the right amount of increased blending power to blends. Give us a call to find out more about this research.

When working with different powder battery chemistries, what are the key factors to consider for optimal OEE?

OEE (Overall Equipment Effectiveness) is a metric used to measure how well a manufacturing process performs. Several factors, including uptime, yield, and quality, contribute to a high OEE score. A high OEE is essential to maintain a competitive edge when it comes to battery manufacturing. After all, this market is highly competitive, and margins are slim.

There are many ways to improve OEE, but one of the most effective is decoupling the manufacturing steps using containers, so that formulation, blending and cleaning can take place simultaneously IBCs are commonly used to decouple a system across the formulation, blending, transportation, storage and transfer of battery powders. This concept is widely used in the chemical, pharmaceutical & food sectors, with proven success. What sets a Matcon system apart is the unique Cone Valve technology within each IBC, which delivers the ability to accurately discharge even the most difficult flowing powders.

With expertly designed connections between the individual processing equipment pieces, you'll benefit from contained materials transfer at all stages. This not only helps to reduce waste and improve efficiency, but it also protects your employees from potential hazards.

Design is also a critical aspect of any battery powder processing operation. The layout of the equipment, the material flow, and the structure of the process all have a significant impact on efficiency. Our team of experts understands the importance of design and can work with you to optimise your operation for maximum efficiency. We use our experience and expertise to ensure that your battery powder processing operation is as efficient as possible.

What to consider when scaling up production?

We understand the importance of a smooth and efficient manufacturing process.

That's why we offer:

Labscale equipment - With this system, you can enjoy predictable performance scaling up to full-scale equipment with a smooth transfer of results from R&D to production. There is no need to reformulate or adapt to full-scale equipment, and production can be completed without a glitch. With the Matcon Labscale system, you can be confident that your research will translate seamlessly into real-world results.

Full-Scale Production - Our IBCs range from 200L to 3500L and, dependent on the application, come in Stainless Steel, Mild Steel and Polyethylene, with the ability to apply inert coatings if needed. And with the added benefit that the Matcon Blender can accommodate multiple container sizes, your manufacturing flexibility and efficiency are instantly improved.

We'll work with you to test and model your process so that we can gain an understanding of the manufacturing challenges that need to be overcome. Then, we'll design a system tailored specifically to your needs.

This approach saves time and money in the long run and ensures that you end up with a product that meets your exact specifications.

We understand your challenges

Over the past decade, we have become one of the most respected names in battery manufacturing powder handling. Our ability to offer maximum flexibility in powder handling solutions is one of the keys to our success. Every client is different and has their own specific needs and requirements, which is why we offer a range of customisable options.

We also appreciate that time is often of the essence, which is why we offer an online consultation service, so you can get started right away.

Alternatively, you can discuss your options with us in person at The Battery Show US, which will be held from 13-15 September in Novi Michigan. We look forward to meeting you and helping you find the perfect powder handling solution for your business.

Topics:

Battery